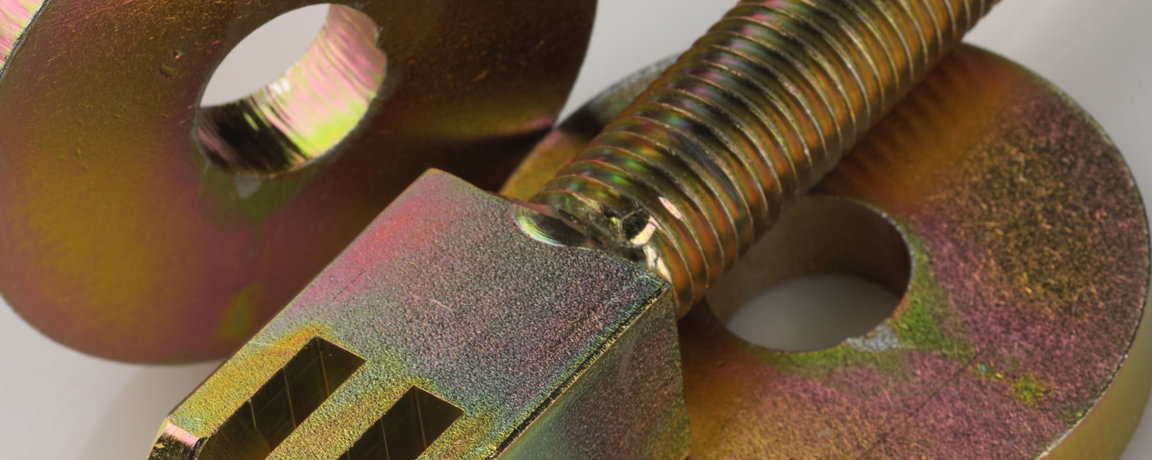

We offer both acid zinc and alkaline Galvanizing, both hang and drum with four types of passivation. Passivation that we are running now is:

- Blue passivation

- Yellow passivation

- Black passivation

- Blank passivation

WHY WE RECOMMEND ALKALINE ZINC PLATING

Below you can read about the comparison between alkaline electrical galvanizing and acid galvanizing

Both alkaline zinc plating and acid zinc plating can be applied to a variety of base metals and alloys. Choosing one over the other is largely a factor in the coating, the base metal, and what will happen to the part after the plating process is complete.

It is important for us at YTSAB to understand the application of the part and the material used to ensure that our plating technology is suitable for your particular project and what requirements it places on alkaline plating of zinc.

Our focus has been on both acidic and alkaline galvanizing. Many of our parts have complex geometries and require even plate distribution. Alkaline zinc plating gives our customers excellent ductility, uniform plating thickness, excellent ductility and controlled distribution of zinc over the entire surface of the part.

Acid zinc is more for the "decorative / eye" it does not have the same protection as galvanizing which is needed in the industry for the protection of the product.

Here we explain the differences between Alkaline versus Acid zinc:

| Alkaline zinc | Acid zinc | |

| Parts | Complex shapes | Castings |

| Evenness | XXX | X |

| Throwing force | XXX | X |

| Gloss | XX | XXX |

| Power efficiency | XX | XXX |

| Corrosion protection | XXX | X |

| Strength | X XXX | X |

.